Your cart is currently empty!

Our responsibility

Our commitment to the environment

Our meals are made to be enjoyed in nature. That’s why we take responsibility for protecting it.

Tackling Food Waste

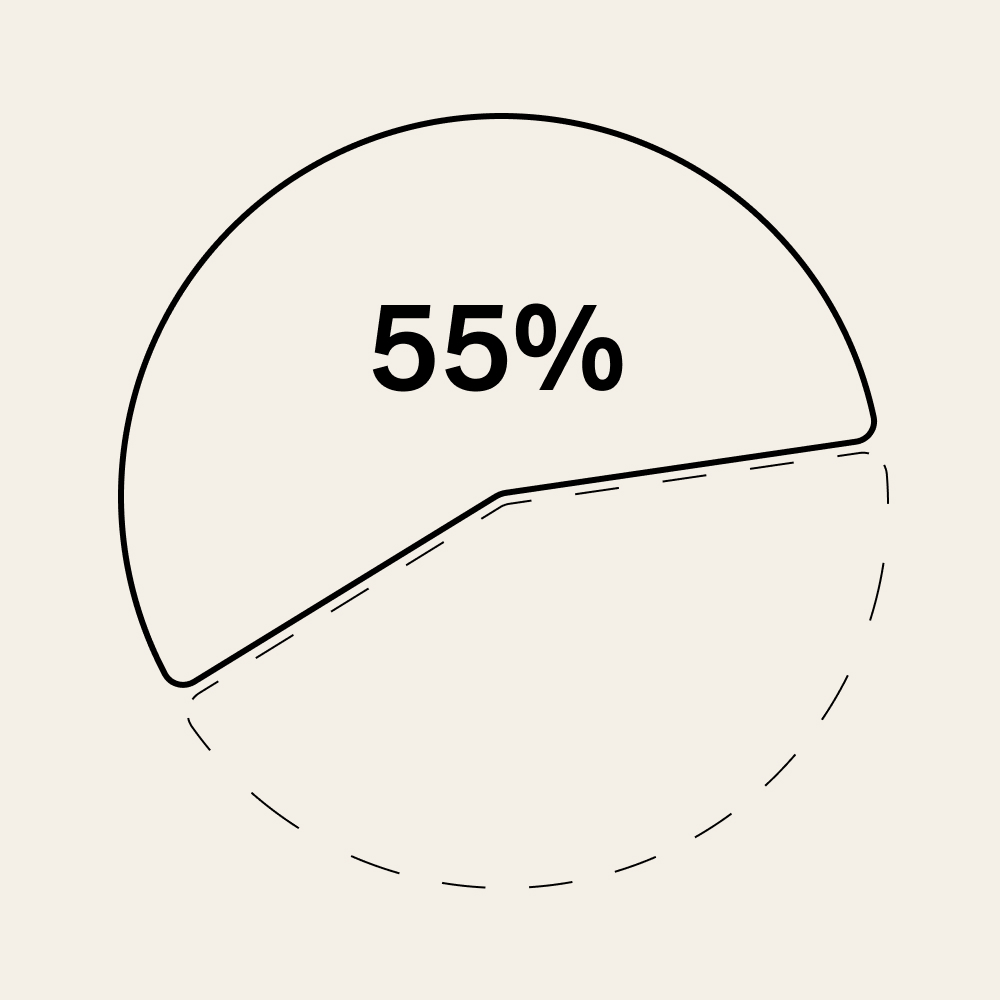

Tackling Food Waste shares our goal to cut waste by 55% with upgrades, smart reuse, and community efforts. See how we turn waste into value.

Choosing Sustainable Materials

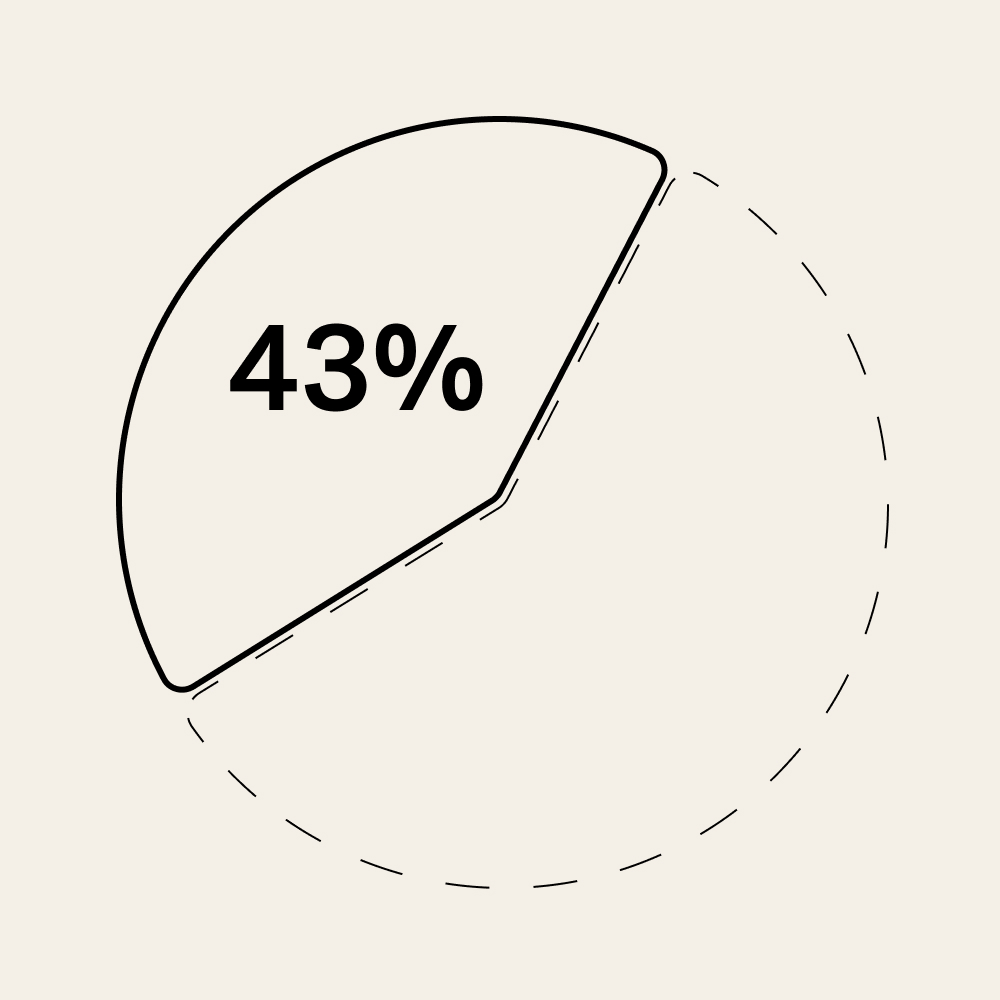

Choosing Sustainable Materials outlines our 2030 goals. Cut waste, boost recycling, and support circular packaging. Read about our progress.

Reducing Energy Consumption

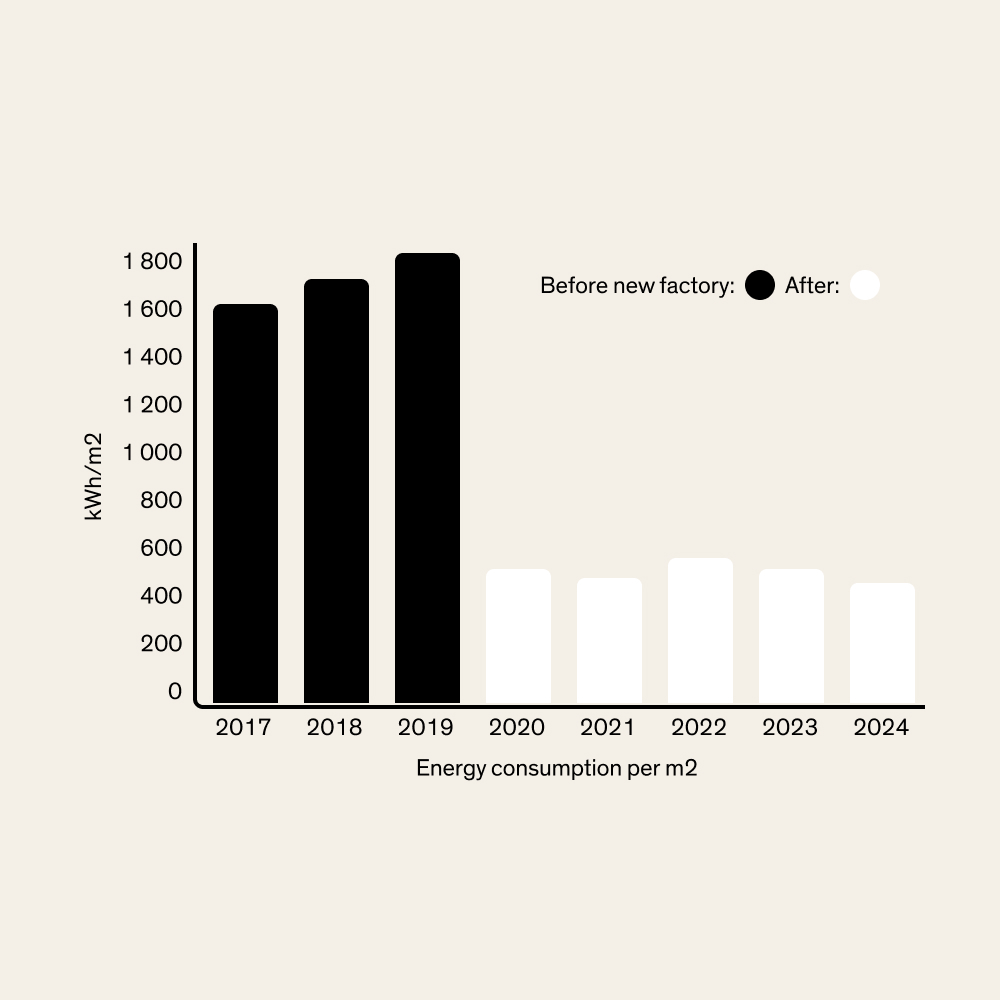

Reducing Energy Consumption shares our 2030 goal: cut energy use 40% with renewables, and reuse systems. Learn how efficiency drives change.

Sustainable Supply Chain

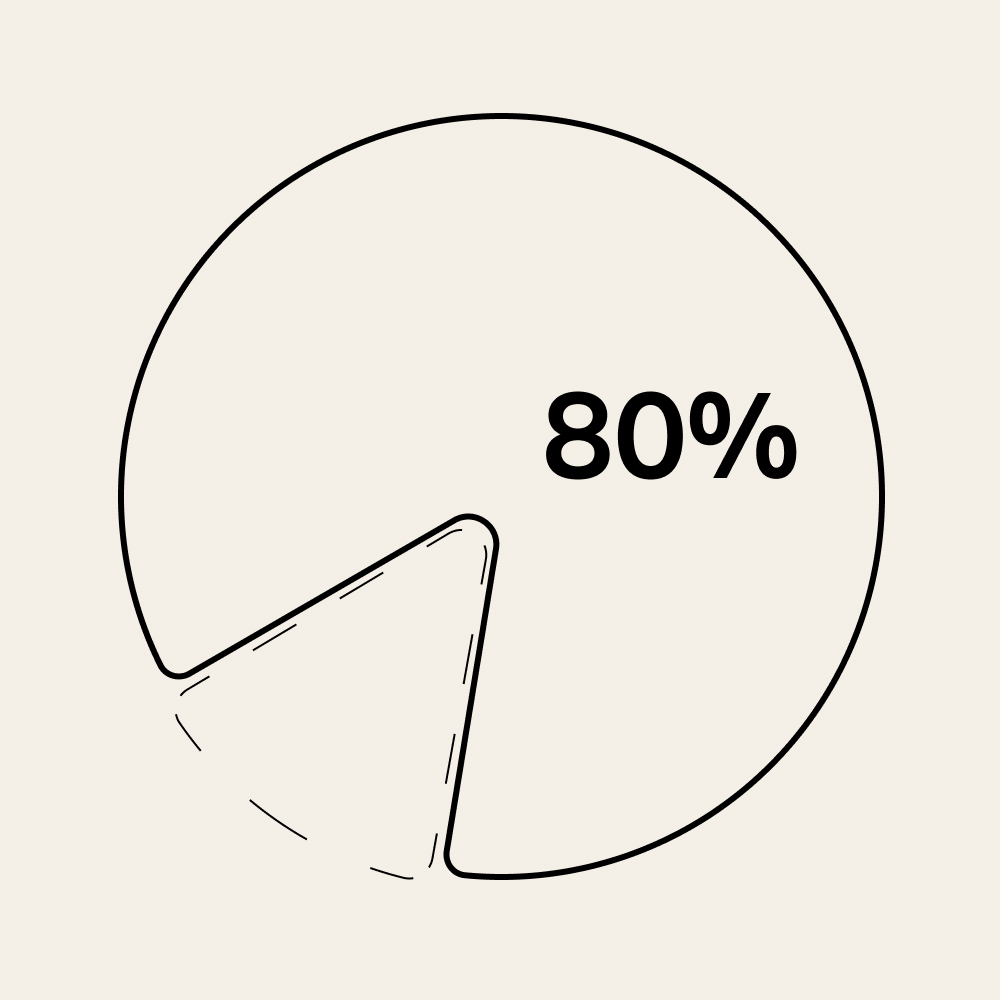

Sustainable supply chain targets 80% certified sourcing by 2030 in human rights, fair labor, and environmental care. Discover our approach.

Perfecting Transport

Perfecting transport shares our 2030 goal to cut emissions 20% with logistics, local sourcing, and low-carbon routes. See how we go greener.

Human and Society

Human and society shares our 2030 vision: safety, nutrition, and inclusion through responsible meals and workplace care. Explore our approach.

Responsibility

Our focus areas

Our responsibility

Tackling Food Waste

To reach climate neutrality, we need to reduce food waste by a large amount. Cutting food waste by 55% is a key step toward reaching our environmental goals and supporting a greener future.

our responsibility

Choosing Sustainable Materials

To reach our sustainability goals, we’ve set high ambitions for reducing waste and improving recycling. Our focus on minimizing waste and finding new ways to reuse materials is an important part of both our environmental work and staying competitive.

Our responsibility

Reducing Energy Consumption

As an Arctic producer, relying on renewable energy comes naturally to us. To meet our sustainability targets, we’re aiming to cut energy consumption by 40% by 2030.

Our commitments

Sustainable Development Goals

We support the UN Sustainable Development Goals and are integrating them into our strategy toward 2030

our responsibility

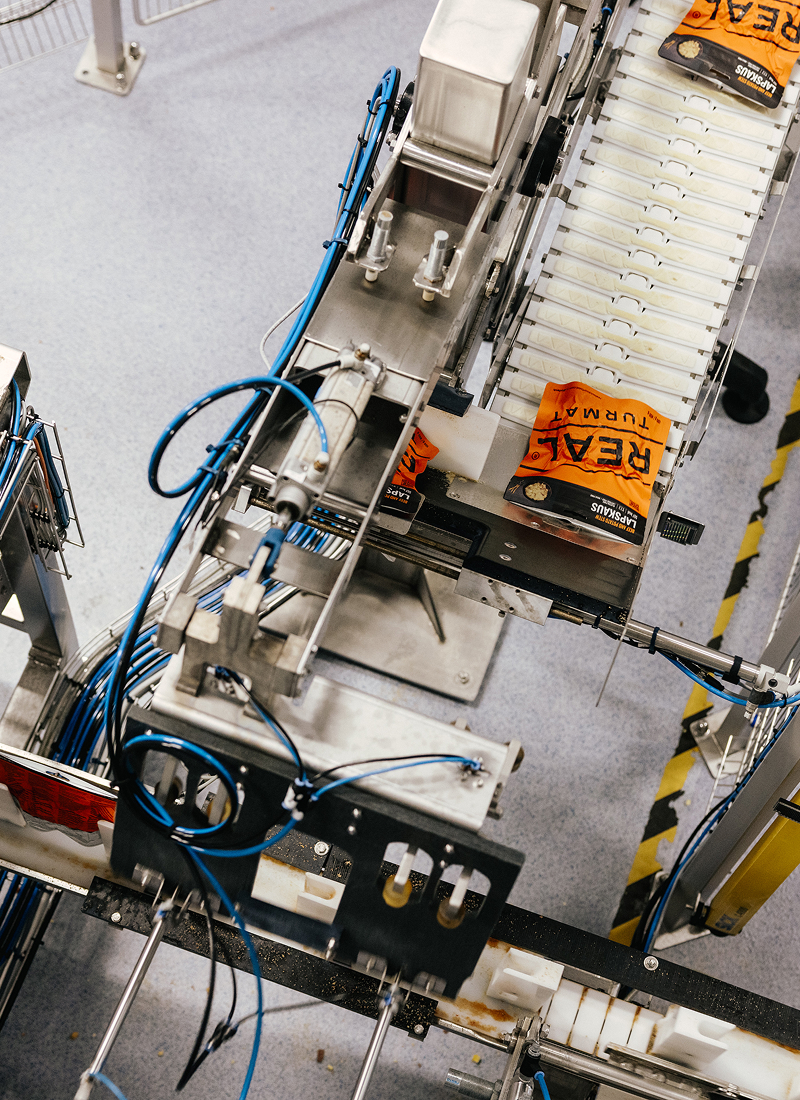

Sustainable Supply Chain

We aim for a sustainable supply chain by prioritizing certified, local suppliers, strengthening partnerships, and using tools like INANKO to track progress.

Our responsibility

Perfecting Transport

Perfecting transport shares our 2030 goal to cut emissions 20% with logistics, local sourcing, and low-carbon routes. See how we go greener.

our responsibility

Human & Society

Human and society shares our 2030 vision: safety, nutrition, and inclusion through responsible meals and workplace care. Explore our approach.

articles

Latest actions

Commitments

Our commitments

Our climate efforts are guided by recognized standards and disclosed through trusted third-party platforms. These commitments ensure our actions are measurable, verified, and aligned with global expectations.