Your cart is currently empty!

Our story

Our freeze-drying technology dates back to the early 1990s when our founder, Rolf Hansen, and the Norwegian Armed Forces collaborated on a project to improve military rations.

How it all started

In the early 1990s, Rolf Hansen worked with the Norwegian Armed Forces to improve their field rations. At the time, soldiers relied on canned food. It was heavy, hard to open, and not well suited for cold climate conditions. From his garage, Rolf developed a freeze-drying method that kept the food’s taste and texture while removing the water. The meals were packed in pouches, making them easier to carry and prepare in the field.

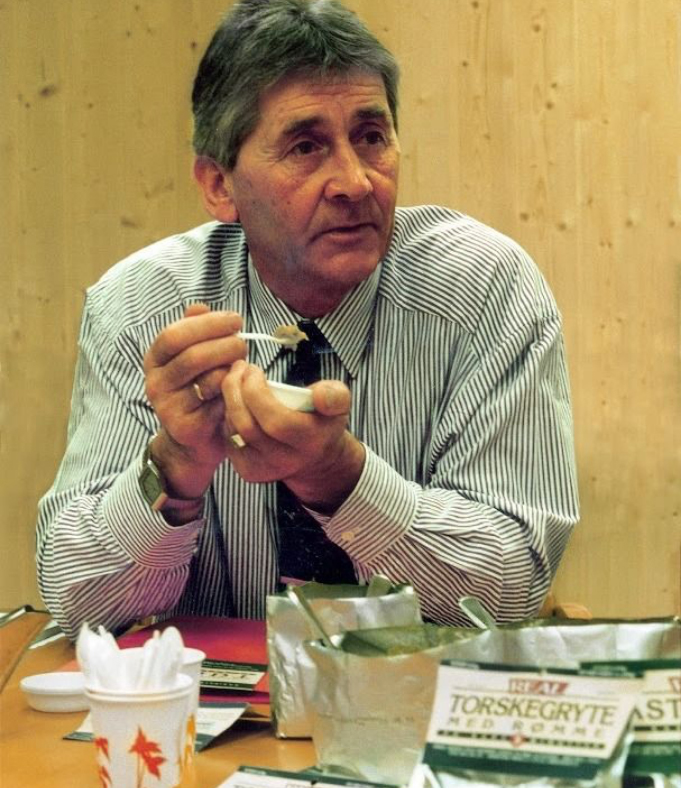

THE FOUnder

Rolf Hansen

Rolf Hansen transformed a simple garage experiment into Drytech, improving military rations and preserving the taste of homemade meals for outdoor enthusiasts.

From tests to military contract

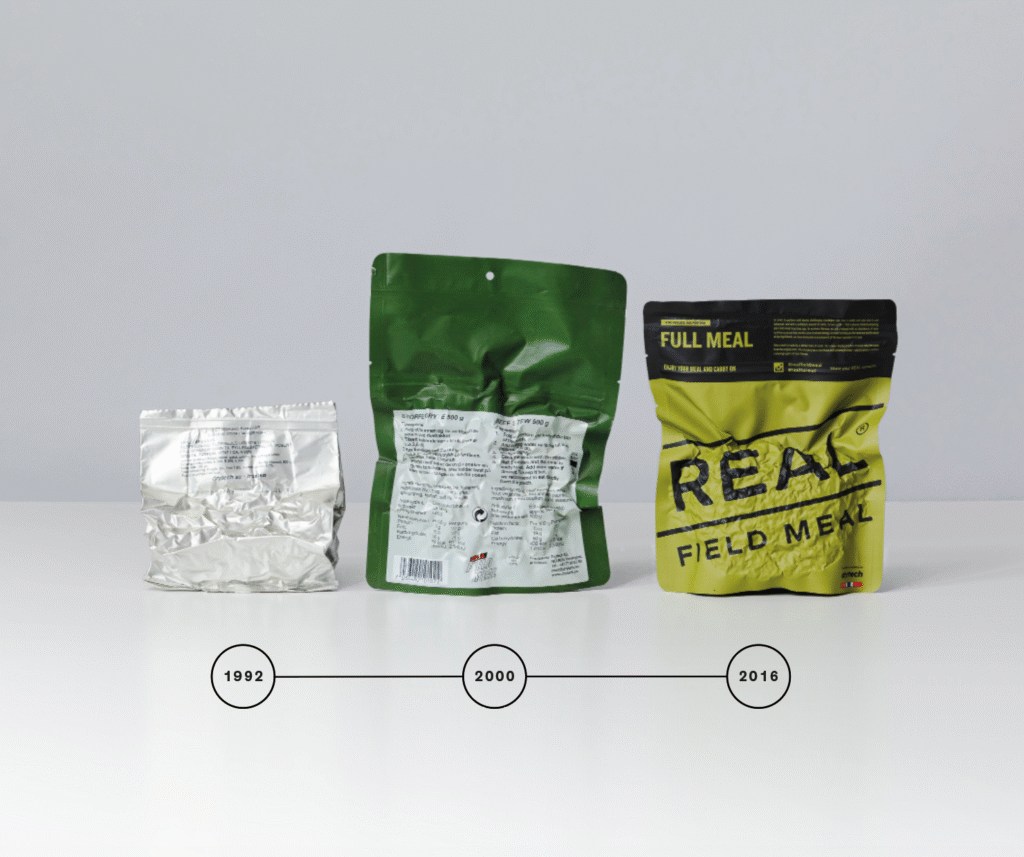

The first meals were made in small quantities and given to the army. The feedback was promising. In 1992, a formal agreement was signed. This marked the beginning of what was then called Drytech – Stews. A few years later, production moved from a test setup into a pilot facility, and then to a full-scale factory in Tromsø in 1994.

REAL Field Meal: From one meal to a full ration

Through the 1990s, Drytech and the Armed Forces worked closely to replace canned food as part of the field rations with freeze-dried food. In the beginning, Drytech only supplied the individual meals, while the Armed Forces handled the packing of a complete ration. In the year 2000 there was another change. Drytech was given the task of assembling the rations as a whole, including all components and packing. At the same time, the name REAL Field Meal was introduced, and a new packing system was put into use: FR2000. Design was still minimal, but the function was clear — to provide soldiers with reliable, calorific dense, light weight meals well suited for arctic warfare.

Scaling up and modernising

As demand increased, so did the need for a more efficient production setup. In 2019, Drytech moved into a new factory on Tromsøya. The new facility allowed for better control, larger output, and long-term stability. Today, this is where all REAL meals are produced.

REAL Turmat: When adventurers took notice

While the focus in the 90s was military supply, a new audience began to discover the meals. In 1997, Norwegian expedition leader Vegard Ulvang brought Drytech meals on his Everest expedition. His feedback helped show that the meals also worked for expeditions. That same year, REAL Expedition Meal was introduced in retail stores, starting in Tromsø. By 2000, the now-familiar orange packaging was launched and the name became REAL Turmat. The product remained the same: freeze-dried food that is easy to prepare and reliable in rough conditions.

Where are we now

Today, REAL Field Meal continues to serve soldiers in the field. REAL Turmat is used by hikers, climbers, emergency responders, and outdoor enthusiasts in many countries. Both were built to solve practical problems. Both are made in Tromsø. And both are shaped by the same principle that started in a garage: meals that work when it matters.